A truck pulls into the loading bay at UPM’s Kaipola paper mill in Jämsä. The driver hops down from the cab, greets the dispatch team, and pulls a smartphone from his jacket pocket. He feeds in the shipment ID, presses ‘start’, and an app begins tracking his 207 km journey from the mill to the customer in Vantaa.

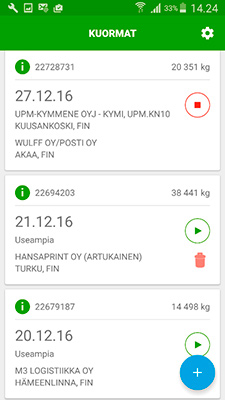

Although the driver handles the app like a pro, it’s in fact a brand-new innovation still in the polishing stages. Called the UPM Mobile Load Tracker (MLT), it is a customized Android solution that is currently being tested as part of a pilot launched in March together with one of UPM’s largest Finnish carriers, VR-Transpoint, who are training 30 drivers to use the system.

Real-time visibility

The app is an answer to growing demand for better customer visibility of the order fulfilment process. The concept was brainstormed last November at the Junction Hackathon by three students, who proposed a system similar to what UPM was already planning internally.

The app is designed for maximum user-friendliness: requiring minimal user feeds, it monitors the progress of shipments in real time, sending comprehensive tracking data to the fingertips of UPM and the customer, anytime, anywhere.

“Its main benefit is visibility, of course,” states Sari Karppala, Process Owner of Logistics at UPM Paper ENA. “The customer can go online and see exactly where their shipment is at any given moment. And, if we see that a truck is running late, we can contact the customer proactively.

In the future, warehouses, too, will benefit from real-time tracking capability. “The loading team will be able to see when the truck is due to arrive and prepare the load in advance for as rapid a turnaround as possible,” adds Karppala.

Logistics is a team effort

The app is also a handy performance indicator, keeping track of which carriers are always on time – and which ones are not. “This data is convenient when we’re negotiating contracts,” notes Karppala.

The pilot will run until the end of Q2, after which UPM will collect feedback from VR-Transpoint and its customers as a basis for further development. The next steps are to integrate a map feature and roll out the system in China.

“Our colleagues at the Changsu mill have expressed great interest,” reveals Karppala. “All in all, this project has demonstrated the importance of close cooperation between different UPM teams working within logistics, as there are so many moving parts.”

“The pilot has been a success,” agrees Henna Luostarinen from VR-Transpoint. “This was a highly agile project that showed the mutual benefit of collaboration. We already have our own truck terminal solution in use in almost 240 trucks. Our goal is to have our drivers use just one solution which produces all requisite data for load tracking. The data is forwarded further to the customer using electronic data interchange.”

One size doesn’t fit all

UPM uses over 300 carriers in Europe – each with different IT capabilities – which means that one app alone cannot cover every need and situation.

“One size doesn’t fit all in logistics. With our huge volumes and so many carriers, we need a combination of solutions to guarantee sufficient coverage. The Mobile Load Tracker is one of three parallel connectivity projects that we currently have in progress at UPM,” notes Antti Ilovuori, Solution Owner of Logistics at UPM Paper ENA.

“As our second project, we’re building new digital interfaces for land transport planning with our leading hauliers in the UK. These are all major carriers with their own fleet management systems for electronic data interchange,” he explains.

MoM’s the word

As the third project, UPM is adopting a new solution in Continental Europe called Mobile Order Management (MoM) developed by the transportation industry-specific global connectivity provider Transporeon. “MoM is very similar to our own mobile app. The driver uses a phone or tablet to send status events, enabling us to track our shipments on the road,” describes Ilovuori.

Over the following months, Ilovuori and his colleagues will continue working on these three interlinked projects, all of which aim to deliver maximum internal and external visibility of order fulfilment.

“When it comes to digitization, we are already ahead our competitors. I barely even remember when we established our first digital connections with our carriers, but it was a long time ago! We don’t have to pick up the phone to check if our carriers have capacity available. All orders are already processed digitally,” notes Ilovuori.

“In the future, our goal is to continue enhancing our digital capability to offer our customers precise, on-time delivery and better visibility. New digital technology offers untold opportunities. Perhaps one day we might even see paper being delivered by self-driving trucks, but for now, our key focus is on carrier connectivity,” he concludes.

Read more

Supply chain did go mobile: tracking application the winning solution in junction

Collaboration with startups and developers accelerates the Biofore revolution

Spirited innovation work across businesses at UPM Youngfore Boot Camp

Silja Kudel